Imagine the last time you grabbed a receipt after making a purchase. Chances are, that receipt was printed on thermal paper. But have you ever wondered how this seemingly ordinary paper creates those crisp, fast prints? Dive into the fascinating world of thermal paper with us!

The Science Behind Thermal Printing

Delving deeper into the science of thermal printing, we uncover a captivating dance between heat and chemistry that brings your printed documents to life.

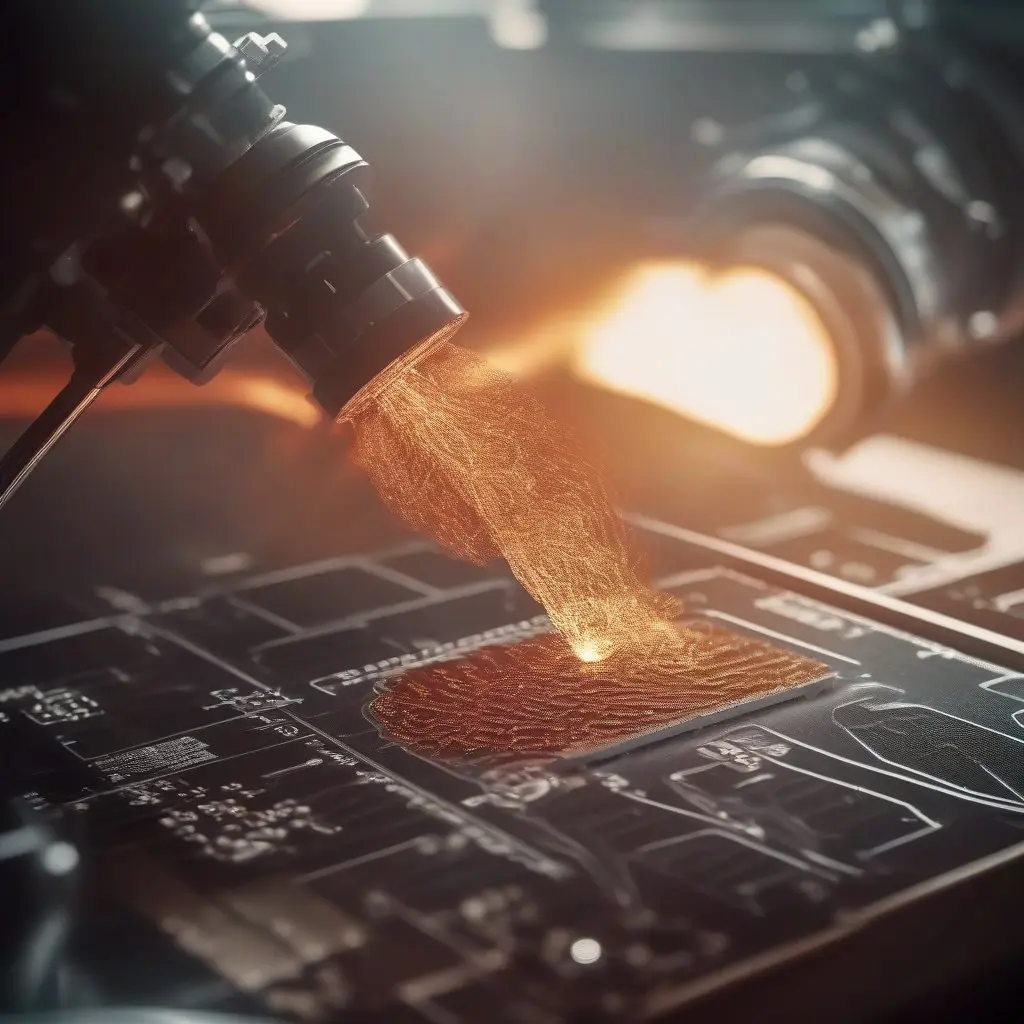

Heat Application

At the heart of thermal paper’s enchantment is the thermal print head. This small but essential component is responsible for transforming plain paper into a canvas of printed wonders. When the print head comes into contact with the paper, it doesn’t just leave a mark—it initiates a meticulously orchestrated process.

Chemical Composition

The secret sauce of thermal paper is its special coating, a carefully concocted mixture of chemicals. This coating contains two main actors: dye and developer. These chemical companions are at the core of the enchantment.

The Magical Reaction

As the thermal print head applies controlled heat to specific areas of the paper, it sets the stage for a chemical spectacle. The heat serves as the catalyst, awakening the developer from its dormant state. With the precision of a chemist’s hand, the developer eagerly reacts with the dye, forming an intricate bond.

Visual Alchemy

This chemical liaison doesn’t go unnoticed. As the dye and developer combine under the influence of heat, they undergo a transformation. The result? A breathtaking display of visible characters or images taking shape on the paper. It’s nothing short of visual alchemy—a symphony of chemistry and heat creating the printed marvels we often take for granted.

So, the next time you receive a receipt or print a label, remember the captivating science unfolding beneath the surface. Thermal printing is not just about ink and paper; it’s a dance of molecules and heat, turning ordinary sheets into extraordinary records of information and artistry.

Types of Thermal Printing

When it comes to thermal printing, understanding the nuances of its two primary types, Direct Thermal and Thermal Transfer, is crucial.

1. Direct Thermal Printing: This method is akin to a precision dance of heat and paper. The print head, with remarkable accuracy, directly applies heat to the thermal paper. Why is this method popular? It’s all about speed and efficiency. Imagine the hustle and bustle of a busy supermarket checkout—direct thermal printing excels in such environments. Whether it’s generating a crisp receipt, a shipping label with tracking details, or a boarding pass for your next adventure, direct thermal printing is the go-to choice when swift, high-quality results are needed.

2. Thermal Transfer Printing: Now, let’s talk durability. Thermal transfer printing introduces an extra player to the game—a ribbon. The print head doesn’t directly interact with the paper. Instead, it heats up the ribbon, which, in turn, transfers ink onto the paper. Why go through this extra step? It’s all about resilience. When your product labels or barcode stickers need to withstand the test of time—perhaps on a product package or a vital shipping label—thermal transfer printing steps up. Its ability to produce long-lasting, smudge-resistant prints is unmatched.

In summary, direct thermal and thermal transfer printing are two sides of the same coin, offering distinct advantages depending on the application’s demands. Whether it’s the swift precision of direct thermal or the durability of thermal transfer, thermal printing continues to shape the modern world, leaving its mark on everything from receipts to retail labels.

Composition of Thermal Paper

To comprehend the inner workings of thermal paper, it’s essential to unravel the layers that make up its composition:

Base Paper – The Bedrock of Quality:

- Base Paper – The Bedrock of Quality:

- The base paper, often unseen but crucial, provides the foundation for thermal paper. It’s like the canvas upon which the magic unfolds. Imagine a smooth, pristine sheet ready to capture every detail.

- Thermal Coating – The Catalyst for Transformation:

- This layer is where the enchantment begins. The thermal coating consists of a precise blend of dye and developer, lovingly applied to one side of the base paper. It’s like the secret potion that awaits activation.

- Protective Layer – Safeguarding the Magic:

- The protective layer plays the role of a guardian. It shields the thermal coating from the elements, ensuring that your prints remain crisp and vibrant over time. It’s akin to a coat of armor for your paper.

As heat meets paper, this trinity of layers collaborates harmoniously. The base paper serves as a canvas, the thermal coating as the artist’s brush, and the protective layer as a shield against wear and tear. The result? Immaculate, detailed prints that leave a lasting impression.

Understanding this composition is like deciphering the secret recipe behind a cherished dish – it adds a dash of wonder to the everyday technology we often take for granted.

The Printing Process

Ever wondered how that receipt magically appears in your hand or those shipping labels get their crisp details? Let’s unveil the fascinating printing process behind thermal paper:

- Heat Activation – Igniting the Magic:

- The journey begins as you press the print button. Within the thermal printer, the thermal print head awakens, radiating controlled heat. This heat is precisely applied to specific areas of the thermal paper.

- Chemical Reaction – The Alchemy of Transformation:

- As the thermal coating encounters the gentle warmth, an enchanting chemical reaction unfolds. The coating, comprising a delicate blend of dye and developer, begins to metamorphose. Heat acts as the catalyst, causing it to change color precisely where it’s touched by this warmth.

- Image Formation – From Heat to Art:

- It’s at this moment that the magic comes to life. The thermal coating’s reaction results in the formation of intricate text or images on the paper. What was once a blank canvas now boasts legible characters and graphics, all thanks to the strategic application of heat.

This elegant dance of heat and chemistry happens in a matter of moments, producing prints that are not only swift but also exceptionally clear and durable. It’s akin to watching a skilled artist craft a masterpiece, only in the realm of technology. So, the next time you hold a freshly printed receipt or label, remember the captivating process that brings it to life.

Advantages of Thermal Paper

In the world of printing, thermal paper stands tall with a set of remarkable advantages that make it a preferred choice in various industries. Let’s delve deeper into these benefits:

Speed – The Need for Swiftness:

One of the most prominent advantages of thermal paper is its lightning-fast printing speed. Whether you’re in a bustling retail environment or managing logistics operations, time is of the essence. Thermal printing ensures that receipts, labels, and documents are produced with remarkable speed, keeping the workflow seamless and efficient

Clarity – Crystal-Clear Prints:

Clarity is paramount when it comes to printed materials. Thermal paper shines in this aspect, delivering prints that are incredibly sharp and easy to read. Whether it’s a sales receipt with intricate transaction details or a shipping label with crucial information, thermal printing ensures that every character and graphic is distinct and legible.

Durability – Resisting the Elements:

Thermal paper is no stranger to challenging environments. It boasts impressive durability, resisting the effects of fading, water, and oils. This resilience is particularly valuable in industries where documents may be exposed to various elements, ensuring that the information remains intact and legible over time.

So, whether you’re racing against the clock, prioritizing clarity, or seeking robust durability, thermal paper emerges as a versatile and advantageous choice. Its ability to combine speed, clarity, and resilience makes it a reliable partner in the world of printing, enhancing productivity and ensuring the longevity of critical information.

Versatile Applications of Thermal Paper

The versatility of thermal paper extends far and wide, finding its invaluable presence in an array of industries where efficient and reliable printing is essential. Let’s explore some common applications:

- Retail – Beyond the Checkout Counter:

- Thermal paper is a staple in the retail landscape, serving as the medium for printing receipts and price tags. At the point of sale, it ensures that transaction details are swiftly documented, and pricing information is presented clearly. This application streamlines the shopping experience for customers and simplifies record-keeping for businesses.

- Healthcare – Precision in Labels:

- In the healthcare sector, precision and accuracy are paramount. Thermal paper plays a pivotal role in this arena by being the choice for patient labels and prescription labels. The high-quality prints it delivers ensure that essential medical information is legible and error-free, enhancing patient safety and the efficiency of healthcare processes.

- Transportation – On-the-Go Efficiency:

- When it comes to transportation, thermal paper keeps things moving seamlessly. It finds its place on boarding passes, ensuring that passengers receive clear and concise travel documentation. Additionally, baggage tags benefit from thermal paper’s durability, withstanding the rigors of luggage handling and ensuring that bags reach their intended destinations.

These are just a few examples of the diverse domains where thermal paper shines. Its adaptability, combined with its ability to deliver swift, clear, and reliable prints, makes it an indispensable tool across various sectors. Whether it’s retail, healthcare, transportation, or beyond, thermal paper continues to play a pivotal role in enhancing operational efficiency and customer satisfaction.

Environmental Considerations

As environmental consciousness grows, it’s natural to question the impact of products like thermal paper. Here’s an insight into the environmental considerations associated with thermal paper:

BPA-Free Alternatives:

One of the primary concerns with thermal paper is the potential presence of Bisphenol A (BPA), a chemical compound. BPA has raised health and environmental concerns. However, the good news is that many brands have responded to these concerns by offering BPA-free thermal paper options. Choosing these alternatives can alleviate worries about potential exposure to BPA.

Recycling Possibilities:

Recycling thermal paper is indeed possible, but it requires some awareness and diligence. Not all thermal paper is suitable for standard recycling processes due to the thermal coating. However, some recycling facilities have the technology to handle thermal paper, especially if it’s segregated correctly. To contribute to recycling efforts, it’s advisable to contact your local recycling facility and inquire about their policies regarding thermal paper.

Environmental Responsibility:

When using thermal paper, individuals and businesses can take steps to minimize their environmental impact. This includes opting for BPA-free paper, using both sides of the paper when applicable, and ensuring proper disposal. Responsible use and disposal can help reduce the environmental footprint associated with thermal paper.

In conclusion, while thermal paper has raised environmental concerns in the past, there are now more eco-conscious options available, such as BPA-free varieties. Additionally, responsible consumption and recycling practices can further mitigate the environmental impact. As sustainability becomes a more prominent consideration, the thermal paper industry continues to evolve to meet these demands.

Troubleshooting Thermal Printing

While thermal printing offers speed and clarity, occasional issues can arise. Here are some troubleshooting tips to address common problems:

1. Fading Prints:

Fading prints can be frustrating, but the issue often stems from improper storage. To prevent fading:

- Store thermal paper in a cool, dry place away from direct sunlight and heat sources.

- Use paper rolls that are not past their recommended shelf life.

2. Print Head Maintenance:

The print head is a crucial component of thermal printers. Over time, it can accumulate dust and residue, leading to print quality issues. To maintain it:

- Regularly clean the print head with a soft, lint-free cloth or a specialized cleaning pen.

- Follow the manufacturer’s guidelines for cleaning frequency and procedures.

3. Uneven Printing:

Uneven printing can result from debris or damage to the print head. To resolve this:

- Inspect the print head for any visible damage or foreign objects.

- If you find debris, gently remove it using a cleaning tool or compressed air.

- If damage is severe, consult a technician for repairs or replacement.

4. Paper Jams:

Paper jams can disrupt printing operations. To prevent and resolve paper jams:

- Use high-quality, undamaged thermal paper rolls.

- Ensure the paper roll is correctly loaded, with no slack or misalignment.

- Follow the printer’s user manual for proper paper loading procedures.

- If a jam occurs, follow the printer’s instructions for clearing it safely.

5. Inconsistent Image Quality:

Inconsistent image quality may be due to variations in the thermal paper’s quality or compatibility issues. To address this:

- Use thermal paper from reputable manufacturers to ensure consistent results.

- Verify that the paper is compatible with your specific printer model.

6. Connectivity Problems:

If you encounter connectivity issues with your thermal printer:

- Check all cable connections and ensure they are secure.

- Restart the printer and connected devices.

- Verify that printer drivers are up-to-date and compatible with your operating system.

By following these troubleshooting tips, you can maintain the efficiency and reliability of your thermal printing system, ensuring that it continues to deliver crisp and clear prints for your various applications.

In conclusion, thermal paper’s working is a blend of science and practicality. It’s the unsung hero behind countless receipts and labels we encounter daily. As technology advances, expect even more innovations in this space. Dive into the world of thermal paper at Sting Bull Ribbon and explore the products that make it all possible!