If you’ve ever been curious about the fusion of the extraordinary world of thermal paper with your everyday printer, you’re in the right place. The intersection of these two seemingly distinct domains is a subject of fascination, and we’re here to shed light on it.

Unveiling the Magic of Thermal Paper

Before we delve further into the fascinating world of thermal paper, let’s take a moment to explore the extraordinary qualities that make it stand out. Thermal paper is no ordinary printer paper; it’s a true marvel in the world of printing technology. It consists of several distinctive layers designed to respond to heat in a way that creates prints without relying on traditional ink or toner.

Imagine this: you’ve likely encountered the wizardry of thermal paper during everyday transactions at cash registers, on tickets, or when receiving printed receipts. Its performance is nothing short of remarkable, and here’s why:

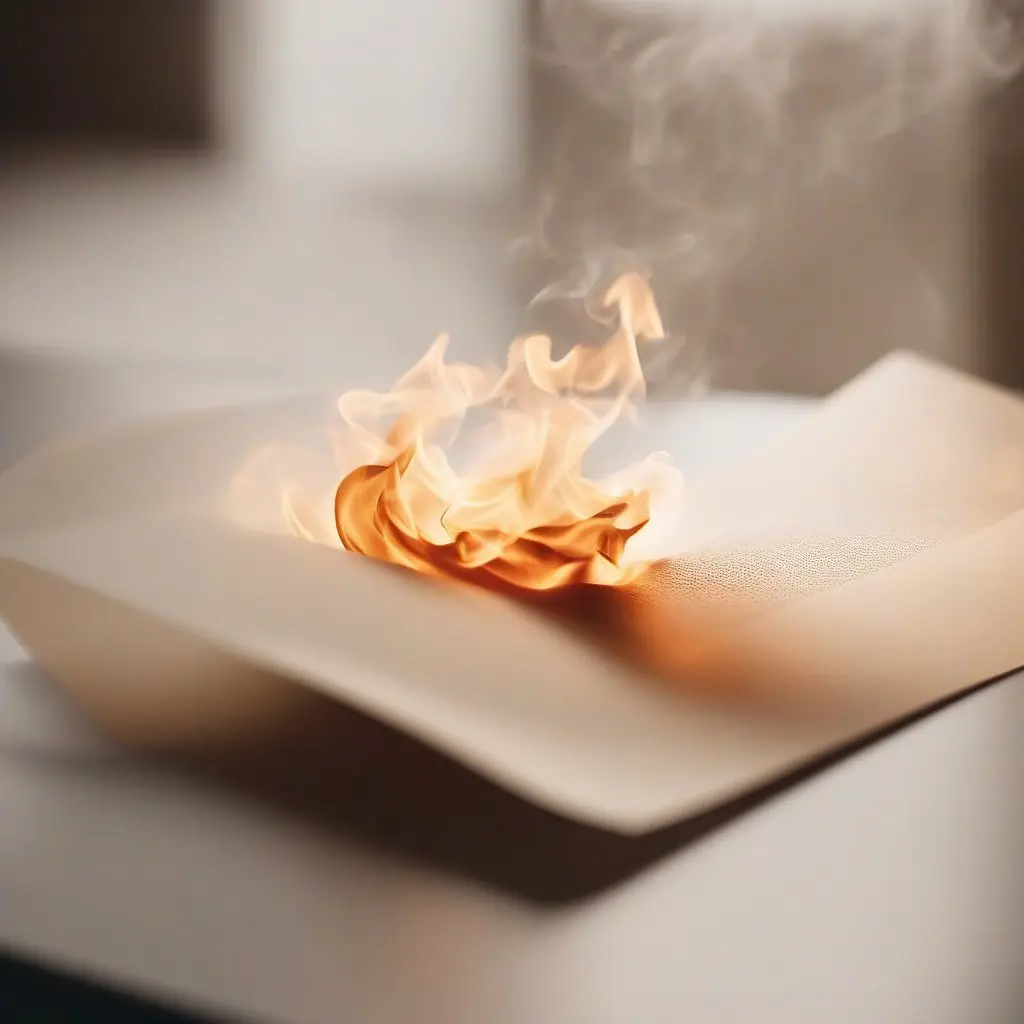

- Heat-Activated Imaging: At the core of thermal paper’s magic lies the unique ability of its layers to react to heat. When heat is applied, a chemical reaction takes place within the paper, resulting in the creation of text or images. This process is in stark contrast to the familiar method of using ink or toner, making thermal paper a game-changer in terms of efficiency and speed.

- No Need for Ink or Toner: One of the standout features of thermal paper is its independence from traditional ink or toner cartridges. This not only reduces the cost associated with consumables but also simplifies the printing process. It’s an eco-friendly choice, as it minimizes waste and eliminates the need for frequent replacement of ink or toner cartridges.

- Swift and Precise Printing: Thermal paper is known for its rapid printing capabilities. Whether you’re at a busy retail store, a transportation hub issuing tickets, or a restaurant providing receipts, thermal paper ensures fast and precise prints, contributing to a seamless customer experience.

- Durability and Longevity: Thermal prints are remarkably resistant to fading and smudging, ensuring that your records and documents remain legible for an extended period. This durability is a critical feature for receipts and documents that need to withstand handling and environmental conditions.

Thermal paper is a technological marvel that combines the convenience of a fast and efficient printing process with the advantage of being ink and toner-free. Its applications go far beyond everyday transactions, and understanding its properties can help you appreciate why it might not be the ideal choice for all types of printers. In the following sections, we will explore the compatibility of thermal paper with standard printers and discuss the potential challenges and alternatives.

But here’s the twist:

“Using thermal paper in a regular printer may not yield the results you expect,” warns the experts at Stingbull Ribbon. The marriage of thermal paper with a standard printer can lead to unexpected challenges.

Potential Perils When Using Thermal Paper in a Standard Printer

- Printer Predicaments:

Your reliable, everyday printer is a workhorse designed to handle a particular kind of paper. Introducing thermal paper into its machinery can be akin to asking a horse to pull a spaceship. The result? A host of printer predicaments that can quickly turn your printing paradise into a nightmare.

- Paper Jams: Your standard printer’s feeding and printing mechanisms are optimized for traditional printer paper. The introduction of thermal paper can disrupt this harmony, causing frequent paper jams and frustrating delays.

- Component Damage: The delicate components within your printer, such as the rollers and sensors, may suffer damage from the unfamiliar texture of thermal paper. This damage could result in costly repairs or even the need for a replacement.

- Hefty Repair Bills: Should your printer suffer severe damage due to the use of thermal paper, you might be facing hefty repair bills. Printer repairs are not known for being budget-friendly, and these unexpected expenses can strain your finances.

- Cost Conundrums:

Thermal paper is undoubtedly a marvel, but it comes at a price. When compared to standard printer paper, thermal paper tends to be on the pricier side. Using it in your regular printer might take you on an unplanned financial adventure with consequences for your budget.

- Expense Increases: The cost of thermal paper can add up, especially if you have high-volume printing needs. The expenses for thermal paper may not align with your budgetary expectations.

- Budgetary Concerns: For businesses and individuals on a tight budget, the financial surprise of purchasing thermal paper can be a cause for concern. Unexpected expenses might necessitate reevaluating your printing supplies strategy.

- Quality Quandaries:

If you’re someone who values top-tier print quality, using thermal paper in a standard printer might not meet your expectations. Standard printers are not optimized for thermal paper, leading to potential quality issues.

- Print Clarity: Thermal paper is designed for optimal clarity and sharpness. However, when used in a regular printer, the output may not match your expectations. Prints might lack the crispness and clarity you desire, impacting the overall quality of your documents.

- Color Fidelity: Standard printers may not reproduce colors with the same vibrancy as specialized thermal printers. If your documents require accurate color representation, using thermal paper in a standard printer could result in disappointment.

- Image Durability: Standard printer ink and toner adhere differently to thermal paper, potentially compromising the longevity and durability of printed images. This can be a concern if your prints need to withstand handling and environmental conditions.

While the idea of using thermal paper in a standard printer may hold appeal, it’s important to consider the potential perils. Paper jams, component damage, unexpected costs, and quality concerns are genuine risks to be aware of. In the subsequent sections, we will explore alternative solutions and best practices to help you make an informed decision regarding your printing needs.

Alternative Avenues for Your Printing Odyssey

If you’re determined to stick with your standard printer, all is not lost. Among our diverse range of printing supplies at Stingbull Ribbon, you’ll find alternatives that are a better fit for your equipment.

Exploring Your Printing Alternatives

If you’ve decided that using thermal paper in your standard printer is not the way to go, fear not. There are alternative paper options that are better suited for your specific printing needs. Let’s take a closer look at these alternatives, each designed to complement different types of printers:

- Inkjet Paper: The Color Enthusiast’s Dream

Inkjet paper is tailored for inkjet printers, making it an ideal choice for anyone who values vivid colors and sharp text. Here’s what sets it apart:

- Color Brilliance: Inkjet paper is engineered to enhance the vibrancy and clarity of your color prints. Whether it’s stunning photographs or vibrant marketing materials, this paper ensures that your images pop with life.

- Text Precision: When you need razor-sharp text, inkjet paper doesn’t disappoint. It’s the perfect choice for documents, reports, and any content where text clarity is a priority.

- Quick Drying: Inkjet paper is designed to absorb ink efficiently and dry quickly. This means your prints won’t smudge, and you can handle them right off the printer.

- Laser Paper: Where Professionalism Meets Precision

If you’re the proud owner of a laser printer, laser paper is your go-to option. It’s the choice of professionals who demand high-quality prints. Here’s why:

- Crisp and Clear: Laser paper ensures that your prints are crisp and clear, whether you’re producing text-heavy documents, brochures, or marketing materials.

- Professional Finish: The paper’s smooth surface provides a professional finish, making it ideal for presentations, reports, and any content where image and text quality matter.

- Consistency: Laser paper excels in producing consistent, high-quality prints. It’s a dependable choice for those who need reliability in every print job.

- Dot Matrix Paper: The Classic Choice for Legacy Printers

If you’re working with a dot matrix printer, dot matrix paper is your trusted companion. It offers compatibility and reliable performance tailored to the unique demands of these printers.

- Continuous Forms: Dot matrix paper often comes in continuous form, which is essential for printers that utilize a feed mechanism to produce multiple copies of a document simultaneously.

- Durability: These papers are built to withstand the impact of dot matrix pins striking the surface repeatedly, ensuring your documents remain legible and intact.

- Wide Range of Applications: Dot matrix paper is versatile and suitable for applications like accounting, order forms, shipping documents, and more, where multiple copies are needed.

Pioneering the Art of Modifying Your Printer for Thermal Paper

For the technologically adventurous individuals pondering the idea of modifying their standard printer to accommodate thermal paper, it’s a journey into uncharted territory. While it’s theoretically possible, it’s important to understand that this endeavor is not for the faint of heart. Here’s an in-depth exploration of what it entails:

The Theoretical Feasibility:

The concept of adapting a regular printer to work with thermal paper hinges on the understanding that thermal paper relies on heat-activated printing. In theory, it’s feasible to modify your printer’s hardware and software to generate the necessary heat to activate thermal paper. However, theory and practice often differ significantly.

Warranty Implications:

A critical consideration is the potential impact on your printer’s warranty. Most printer warranties explicitly state that any unauthorized modifications will void the warranty. Proceeding with printer modifications could leave you without manufacturer support in case of issues or malfunctions.

Technical Challenges:

The process of modifying a standard printer for thermal paper is complex and intricate. It typically involves making adjustments to the heating mechanisms, print head, and possibly even the printer’s firmware. These modifications require a deep understanding of printer hardware and software, which is beyond the scope of the average user.

Unpredictable Results:

Another factor to bear in mind is the unpredictability of the results. Even with technical expertise, there’s no guarantee that the modified printer will perform flawlessly with thermal paper. You may encounter issues like uneven heating, inconsistent print quality, and frequent paper jams.

Professional Guidance:

If you’re genuinely committed to pursuing this path, it’s highly advisable to seek the assistance of professionals who specialize in printer modifications. These experts can provide the technical expertise required to ensure the modifications are carried out correctly and safely. However, be prepared for associated costs as professional services in this domain can be expensive.

Proceeding with Caution:

Above all, the process of modifying a printer for thermal paper should be undertaken with the utmost caution. It’s not a DIY project for the casual enthusiast. Even with professional guidance, it’s crucial to understand the potential risks and limitations.

The idea of modifying a standard printer for thermal paper is theoretically possible but fraught with challenges and potential drawbacks. It’s not a journey to be taken lightly, as it involves technical complexity, warranty concerns, and unpredictable results. If you’re determined to venture into this territory, professional assistance is the safest route, but it’s vital to be aware of the costs and potential limitations. For most users, opting for a printer that’s compatible with thermal paper is the more practical and reliable choice.

Mastering the Craft of Handling Thermal Paper

If you’re unwavering in your decision to use thermal paper, whether with the appropriate printer or for specific applications, mastering the craft of handling this unique paper is essential. Here are some additional guidelines to ensure you make the most out of your thermal paper:

Storage Wisdom: Extending the Paper’s Lifespan

Proper storage of thermal paper is the key to preserving its quality and longevity. Consider these storage tips:

- Cool, Dry Place: Store your thermal paper in a cool and dry environment. Temperature fluctuations and humidity can impact the paper’s performance. The more stable the storage conditions, the better.

- Shield from Sunlight: Keep thermal paper away from direct sunlight. Prolonged exposure to UV rays can lead to paper discoloration and may affect the chemical coating’s stability.

- Use Protective Packaging: If you have a large supply of thermal paper, consider using protective packaging, such as plastic wrap or a resealable bag, to shield it from environmental factors.

- Handle with Tender Loving Care: Ensuring Print Quality

Thermal paper is sensitive, and how you handle it can significantly influence print quality and longevity. Follow these practices:

- Avoid Bare-Hand Contact: Refrain from touching the paper’s surface with bare hands. Natural oils and dirt from your skin can transfer to the paper, affecting print quality and potentially causing premature fading.

- Use Clean Hands or Gloves: When handling thermal paper, use clean hands or wear disposable gloves to minimize the risk of contamination. This extra step can go a long way in maintaining the paper’s integrity.

- Store Unused Rolls Properly: If you have unused rolls of thermal paper, store them in their original packaging or a protective container to prevent exposure to external elements.

- Printer Maintenance: Keeping the Print Path Clear

If you’re using thermal paper with the right printer, regular maintenance is paramount to ensure smooth operation and prevent common issues like paper jams and damage. Consider the following:

- Scheduled Cleaning: Establish a routine for cleaning your printer’s print head and feed mechanisms. Dust and debris can accumulate over time, causing disruptions in the print path.

- Calibration Checks: Periodically check and calibrate your printer to ensure that it’s optimized for thermal paper. This step can help maintain print quality and reduce the risk of misfeeds.

- Use High-Quality Ribbons: If your printer requires thermal ribbons, use high-quality, compatible ribbons to ensure the best possible print results.

By embracing these additional guidelines, you can become a true master in the art of handling thermal paper. Proper storage, gentle handling, and regular printer maintenance are your allies in preserving the integrity of your thermal paper, allowing you to enjoy its benefits without any unwelcome surprises.

In Conclusion

In summary, while the prospect of using thermal paper in a standard printer might be alluring, the prudent choice is to opt for paper explicitly designed for your printer. At Stingbull Ribbon, we understand the importance of selecting the right supplies for your printing endeavors.

Your printer is a trusty companion, deserving the utmost care. So, explore your options, make informed decisions, and let your printer weave its magic, bringing your ideas to life.

For all your printing needs, explore our range of thermal paper products and other printing supplies.

Make the smart choice and embark on a delightful printing journey!