Thermal printers have become an integral part of our lives, widely used across various industries. But have you ever wondered if they require special paper? In this article, we will delve into the realm of thermal paper, its types, advantages, and compatibility with thermal printers.

The Basics of Thermal Printing

Thermal printers operate on a fascinating principle. They employ heat to create images and text on specially designed paper. This process eliminates the need for traditional ink or toner cartridges, making it cost-effective and environmentally friendly.

Types of Thermal Paper

As we delve deeper into the world of thermal paper, it’s essential to understand that not all thermal paper is created equal. There’s a rich diversity in the types of thermal paper available, each tailored to specific needs and applications. Let’s embark on a journey to explore the fascinating array of thermal paper options.

The Workhorse: Standard Thermal Paper

Standard thermal paper is the backbone of thermal printing. It’s the go-to choice for most thermal printers and is readily available in various sizes and quantities. This type of thermal paper features a base layer with a heat-sensitive coating.

Its versatility makes it ideal for everyday applications, such as printing receipts, labels, and tickets. Whether you’re running a retail store, a shipping department, or a restaurant, standard thermal paper is a dependable choice that offers excellent print quality.

Safety First: BPA-Free Thermal Paper

In recent years, concerns have arisen about the use of Bisphenol A (BPA) in thermal paper. BPA is a chemical that has raised health and environmental concerns. To address these worries, manufacturers have developed BPA-free thermal paper.

This type of thermal paper offers the same exceptional print quality as standard thermal paper but without the potential health risks associated with BPA. Brands like Thermal Paper Collection offer BPA-free options, ensuring both safety and quality.

Tailored to Unique Needs: Specialty Thermal Paper

For specialized applications, specialty thermal paper steps in to meet unique requirements. This category encompasses a diverse range of thermal paper options designed to excel in specific conditions or industries. Some notable examples include:

- Weather-Resistant Paper: Built to withstand exposure to the elements, weather-resistant thermal paper is perfect for outdoor use, such as parking ticket printing.

- Freezer-Grade Paper: With exceptional resistance to low temperatures, freezer-grade thermal paper is essential for labeling frozen goods in grocery stores and warehouses.

- High-Temperature Paper: Certain industries, like manufacturing, require thermal paper that can endure high temperatures without compromising print quality.

- Security Thermal Paper: Featuring additional security features like watermarks or tamper-evident properties, this type of thermal paper is used for sensitive documents and certificates.

Making the Right Choice

Choosing the right type of thermal paper is crucial to ensure optimal print quality, durability, and performance. Consider the specific needs of your application. Are you printing receipts for a retail store? Opt for standard thermal paper. Concerned about BPA? Go for the BPA-free option. Do you require specialized performance in extreme conditions? Explore the world of specialty thermal paper.

In the end, understanding the diversity of thermal paper empowers you to make an informed choice that aligns with your unique printing requirements. Whether you’re striving for everyday efficiency or seeking a specialized solution, the world of thermal paper has you covered.

The Numerous Advantages of Using Thermal Paper

As we journey further into the world of thermal paper, it’s essential to explore the multitude of advantages it offers. Thermal paper’s unique properties make it an attractive choice for various applications, ranging from point-of-sale systems to medical devices. Let’s delve into the numerous benefits of using thermal paper.

1. Durability and Longevity

Thermal paper is renowned for its exceptional durability. Unlike traditional paper, thermal prints don’t rely on ink or toner that can smudge, fade, or deteriorate over time. Instead, they rely on a heat-sensitive coating that ensures longevity. Whether you’re printing essential receipts or shipping labels, thermal paper can withstand the test of time, ensuring that your documents remain legible and intact.

2. Cost-Effectiveness

One of the most significant advantages of thermal printing is its cost-effectiveness. Thermal printers eliminate the need for ink or toner cartridges, which can be expensive to replace. This translates to substantial long-term savings for businesses, especially those with high-volume printing needs. The absence of consumables also simplifies maintenance, reducing downtime and operational costs.

3. Eco-Friendliness

Environmental sustainability is a growing concern, and thermal printing aligns with eco-friendly practices. Since thermal paper doesn’t require ink or toner, it reduces the environmental impact associated with their production, usage, and disposal. Furthermore, many brands now offer recyclable thermal paper options, contributing to a greener planet.

4. Smudge and Fade Resistance

Traditional paper documents, especially those printed with ink, are susceptible to smudging and fading. This isn’t the case with thermal paper. Thermal prints are resistant to smudging, ensuring that the information remains clear and legible even when exposed to moisture or contact. They also resist fading over time, preserving the integrity of vital records.

5. High Print Speeds

Thermal printers are known for their rapid print speeds. The absence of the need to wait for ink or toner to dry allows for immediate document handling. This speed is particularly advantageous in busy settings like retail stores, logistics centers, and healthcare facilities, where efficiency is paramount.

6. Minimal Maintenance

Thermal printers are remarkably low-maintenance. They have fewer moving parts compared to traditional printers, which reduces the likelihood of mechanical failures. Routine maintenance primarily involves paper roll replacement, making them easy to manage even for users with limited technical expertise.

7. Sharp and Legible Output

The precision of thermal print heads ensures sharp, legible text and high-resolution graphics. Whether you’re printing barcodes, shipping labels, or receipts, thermal prints are consistently clear and easy to read. This level of print quality is essential in applications where accuracy and detail matter.

8. Versatile Applications

Thermal paper finds applications in a wide range of industries, from retail and hospitality to healthcare and logistics. Its versatility makes it suitable for printing receipts, labels, tickets, medical charts, and more. Whatever your business or organization, thermal paper offers a reliable solution tailored to your specific needs.

The advantages of using thermal paper extend beyond the surface. Its durability, cost-effectiveness, eco-friendliness, and print quality make it an indispensable choice for businesses seeking efficiency and sustainability. Whether you’re looking to streamline operations, reduce costs, or enhance document longevity, thermal paper stands as a dependable ally in achieving these goals.

Ensuring Seamless Compatibility with Thermal Printers

In the realm of thermal paper, compatibility with thermal printers is a critical factor that can significantly impact the quality and efficiency of your printing operations. Let’s delve into the importance of ensuring seamless compatibility and how it can enhance your overall printing experience.

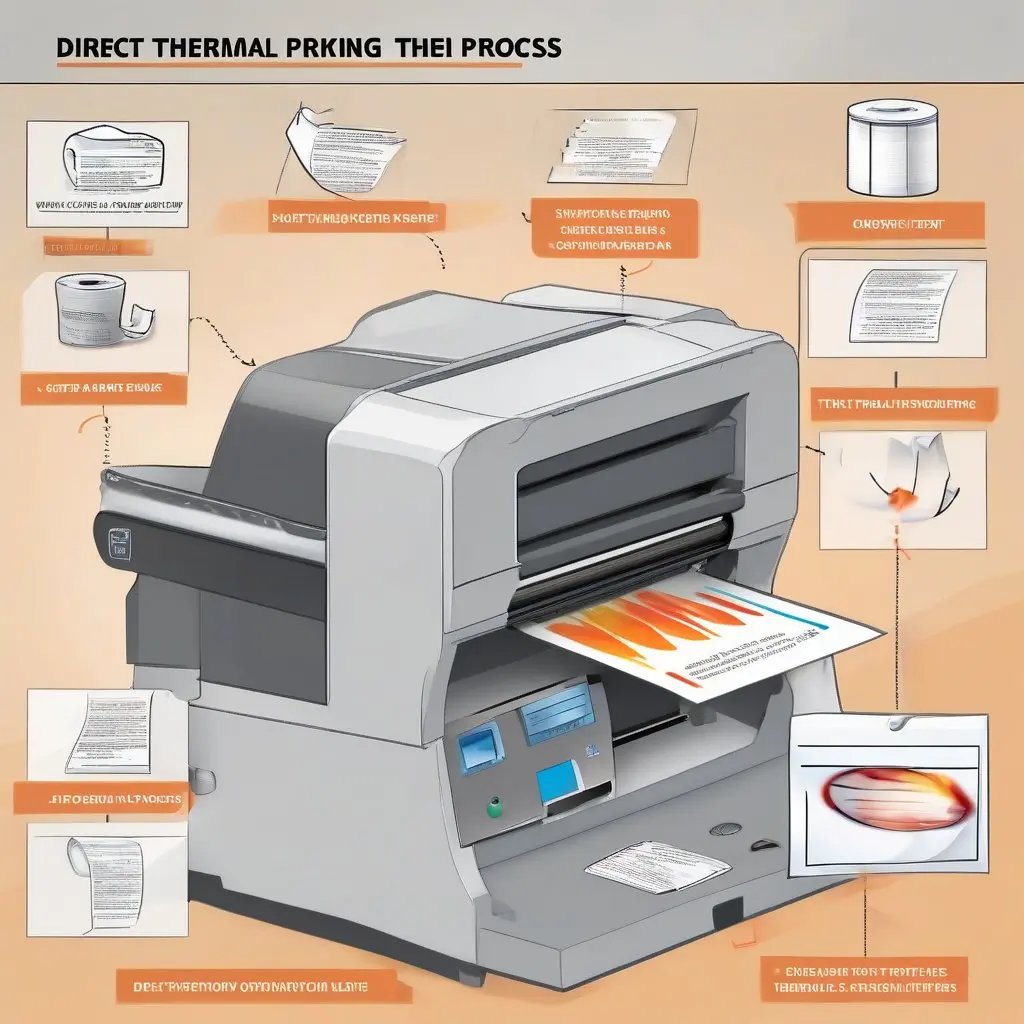

1. Understanding Thermal Printers

Before exploring compatibility, it’s essential to have a basic understanding of thermal printers. These printers employ a straightforward yet highly efficient mechanism that relies on heat to produce images and text on thermal paper. Two main types of thermal printers are widely used:

- Direct Thermal Printers: These printers apply heat directly to the thermal paper, causing the coated areas to darken and form the desired prints. They are commonly used for applications like receipts and labels.

- Thermal Transfer Printers: In thermal transfer printing, a thermal print head transfers ink from a ribbon onto the thermal paper, creating the image or text. This method is preferred for tasks requiring higher durability, such as barcode labels and shipping labels.

2. Choosing the Right Thermal Paper

The compatibility journey begins with selecting the appropriate thermal paper for your specific printer type. Different thermal printers have varying requirements when it comes to paper, including:

- Size: Ensure that the thermal paper size matches the printer’s specifications. Common sizes include 2.25 inches, 3.125 inches, and 4 inches.

- Coating Type: Direct thermal printers necessitate thermal paper with a heat-sensitive coating, while thermal transfer printers require paper compatible with the type of ribbon used.

- Core Size: Consider the core size of the thermal paper rolls, as it should fit the printer’s spindle for smooth feeding.

- Sensitivity: Some printers may require a particular level of paper sensitivity adjustment for optimal printing. Be aware of your printer’s sensitivity settings and choose paper accordingly.

3. Avoiding Common Pitfalls

To ensure compatibility and prevent printing issues, be mindful of the following pitfalls:

- Using the Wrong Paper Type: Using direct thermal paper in a thermal transfer printer or vice versa can lead to subpar print quality and damage to the printer.

- Incorrect Loading: Improperly loading the paper into the printer can result in paper jams and print misalignment. Always follow the printer manufacturer’s instructions for loading thermal paper.

- Neglecting Maintenance: Regularly clean the print head and perform routine maintenance to prevent buildup and ensure consistent print quality.

4. Reliable Suppliers

Partnering with reliable suppliers is crucial for obtaining high-quality, compatible thermal paper. Look for suppliers that offer a wide range of thermal paper options designed for various printer types. Established suppliers often provide compatibility guidance and support.

5. Testing and Calibration

Before implementing thermal paper in your printing environment, conduct testing and calibration to ensure that the paper and printer are working harmoniously. This step helps identify and resolve any compatibility issues before they disrupt your operations.

In conclusion, compatibility with thermal printers is the cornerstone of a smooth and efficient printing process. By understanding your printer’s requirements, choosing the right thermal paper, avoiding common pitfalls, partnering with trusted suppliers, and conducting thorough testing, you can unlock the full potential of thermal printing technology and enjoy the benefits of precision, reliability, and cost-effectiveness.

Conclusion

In conclusion, while thermal printers do not necessarily require “special” paper, choosing the right type can significantly impact the quality and longevity of your prints. Whether you opt for standard, BPA-free, or specialty thermal paper from collections like Thermal Paper, it is essential to consider your specific requirements. In the end, thermal printing offers a cost-effective, eco-friendly, and reliable solution for various applications.

So, if you are wondering whether thermal printers need special paper, the answer is: not always, but choosing the right thermal paper matters.